In today’s textile industry, having the best fabric printing machine | HGS Machines can truly determine your competitive edge. Whether you are a small-scale manufacturer or a full-fledged production house, choosing the right machine of this kind is essential. In this blog we’ll explore why the banner term “Best Fabric Printing Machine | HGS Machines” matters, what HGS Machines offers, how to evaluate the machines, and how you can decide which one is right for your business.

Why the Keyword “Best Fabric Printing Machine | HGS Machines” matters

The phrase “Best Fabric Printing Machine | HGS Machines” is more than a marketing tagline. It reflects a specific search intent: businesses wanting a high-quality printing machine for fabrics, specifically from the brand/model range of HGS Machines Pvt Ltd (often called HGS). By targeting this exact phrase:

You catch traffic from people searching for “fabric printing machine” + “HGS Machines”.

You align with buyers who already know the brand or are considering it.

You highlight your machine as one of the “best”, which helps in decision-making for the user.

In short: when someone types exactly that keyword, you want your blog to show up — giving you a chance to convert searches into leads.

About HGS Machines: Company & Offerings

HGS Machines Pvt Ltd is headquartered in Ghaziabad, Uttar Pradesh, India and operates in the digital textile printer manufacturing domain. They describe themselves as “India’s leading digital textile printers and fabric printers manufacturer in Delhi/NCR” region.

Key Facts

They offer digital fabric printing machines, direct-to-fabric printers, sublimation machines, pigment-based printers and more.

Their range covers various head configurations (4-head, 8-head, 16-head, 32-head) to match different production capacities.

They claim strengths in “high speed precision printing for every fabric” and “eco-friendly technology with water-based inks”.

They provide training, on-call service and after sales support — an important factor for industrial machines.

This background sets the stage: the best fabric printing machine | HGS Machines phrase is justified because HGS aims to deliver top-tier machines with wide applicability.

What Does “Best Fabric Printing Machine | HGS Machines” Mean in Practice?

When you see the term “best fabric printing machine”, what attributes should you expect? And how does HGS match them?

1. Print Quality & Resolution

A top fabric printing machine must deliver crisp, vibrant prints across fabric lengths and types. HGS Machines mentions usage of advanced printheads (like Ricoh Gen6) and digital precision for their machines.

This means your prints will have sharp detail even on fine fabrics like silks or blended textiles.

2. Speed & Production Capacity

For fabrics, especially large orders, you need a machine that can print metres per hour reliably. HGS claims a range of machines suitable for industrial scale production — for example the 32-head “Blaze” model in their product range.

Thus the “best” machine must match your production output needs.

3. Fabric & Ink Compatibility

Different fabrics (cotton, silk, polyester, viscose) require different ink types (reactive, pigment, sublimation). HGS covers direct fabric printers and sublimation printers – meaning fabric variety is covered.

A machine that is “best” allows you to switch between fabrics or handle multiple types.

4. Automation & Ease of Use

A best-in-class machine will reduce operator burden: automatic fabric feeding, tension control, alignment, cleaning. HGS mentions “smart automation for seamless production”.

This lowers errors and downtime.

5. Support & Service

Even the best machine fails its promise if after-sales support is weak. HGS emphasises training and on-call service to keep machines running.

Thus the best machine is one supported by the manufacturer.

6. Cost-effectiveness & ROI

A machine may be excellent technically but if cost, consumable wastage, maintenance are high, ROI suffers. HGS aims at “economical price” and “reduce customer cost”.

Hence the “best” machine is one that gives balance of cost vs benefit.

Key Models from HGS Machines

While the exact specs for each model may need direct contact for quoting, the following models illustrate their lineup and how they address the “best fabric printing machine | HGS Machines” promise.

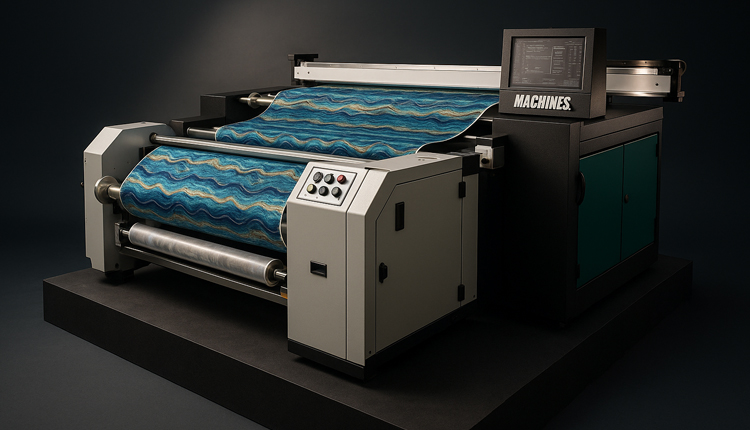

HGS Machines DIR-4PS Tejas R (4 ps)

An industrial roll-to-roll digital textile printing machine from HGS (model "/Hgs-Dir-Tejas R(4ps)"). According to listing: Fabric width around 1650 mm, suitable for viscose etc.

Best for mid-scale production where you need automatic roll feed and consistent output.

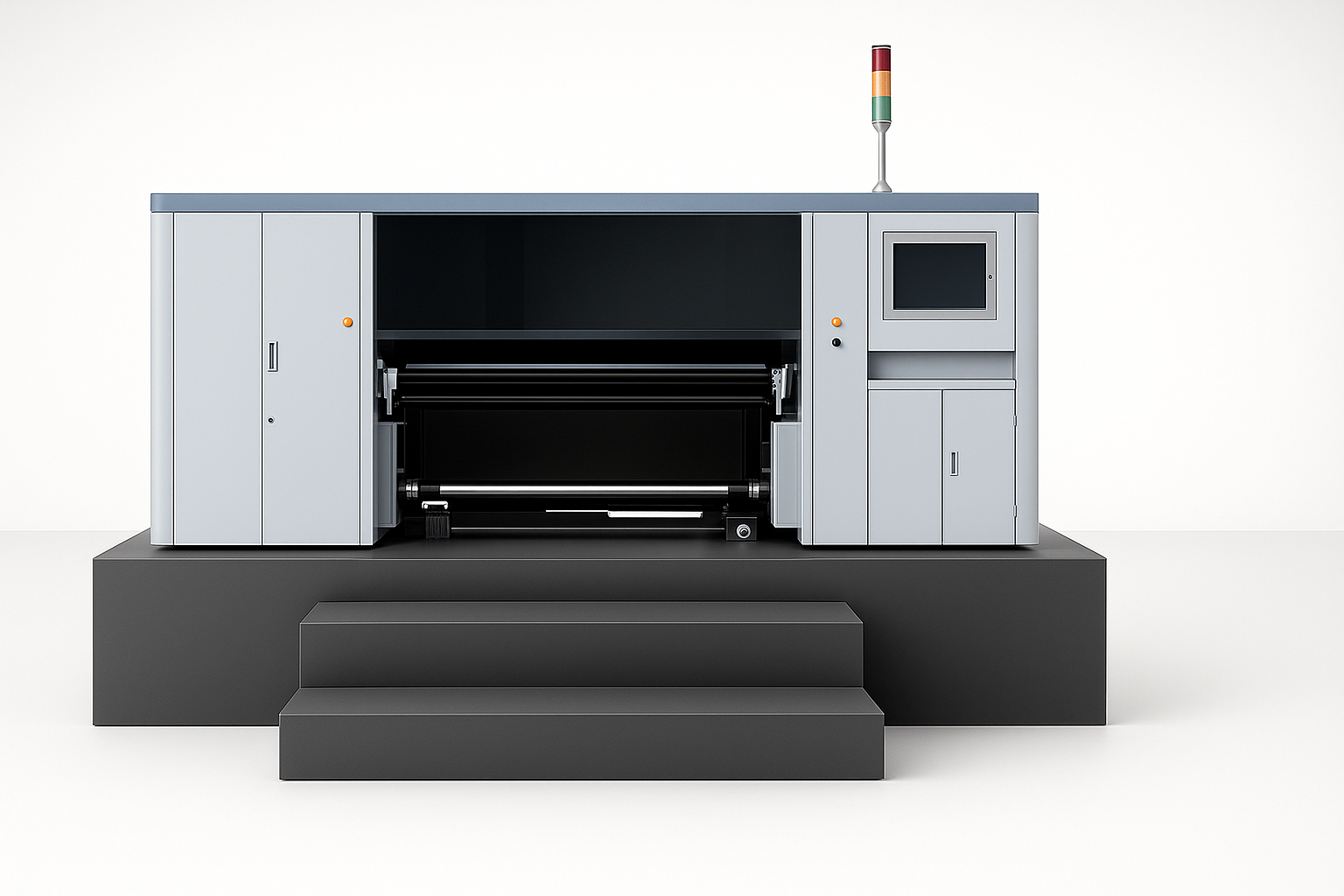

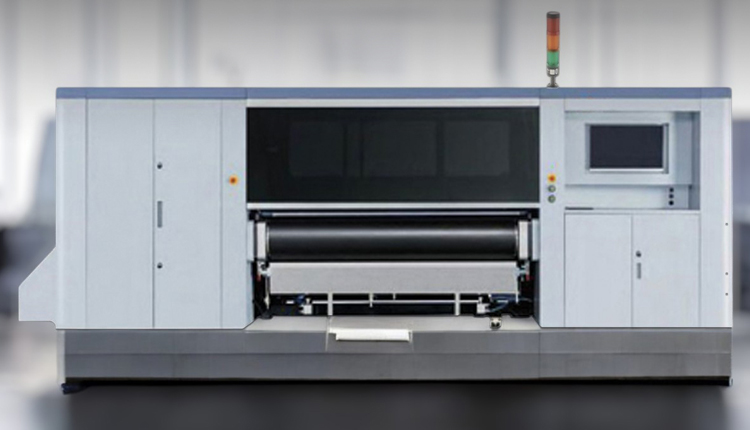

HGS Machines Industrial Digital Textile Printing Machine

Generic industrial digital textile printing machine listing; high capacity, suitable for large fabric printers. Gives you the scale needed for bulk textile production.

High Speed Digital Textile Printing Machine

Though not branded explicitly as HGS, this category aligns with what HGS offers (32-head high-speed machines). Ideal for businesses demanding very high output.

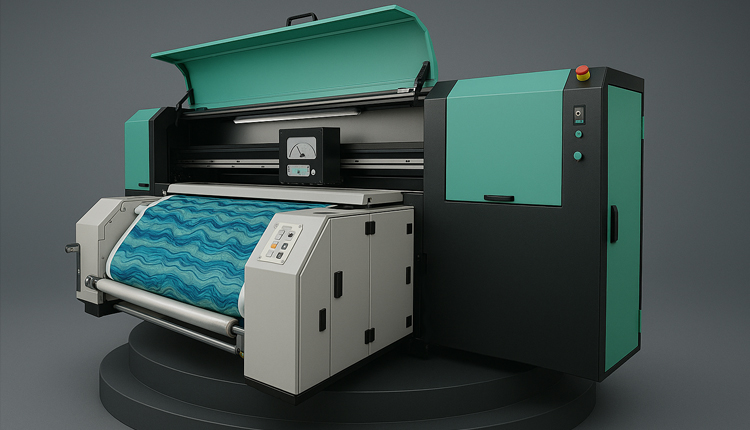

Cotton Fabric Digital Textile Printer Automatic Grade

Focuses on cotton fabric with automatic grade features. Good for businesses specialising in cotton textile printing who still want automation and reliability.

Silk Digital Textile Printing Machine For Fabric

Specialised machine for silk fabric printing — demonstrates HGS’ range across fabric types.

Fabric Automatic Digital Textile Printing Machine

Top-tier machine with full automation and high capacity — suitable for large scale manufacturers.

Textile Printing Machinery

Broader category machine for printing on fabric; good for complementary production lines or diversification.

Durable Digital Textile Printers

Focuses on durability, which is key for industrial use and aligns to “best fabric printing machine | HGS Machines”.

Brief highlights for each:

DIR-4PS Tejas R (4 ps) – Entry / mid level roll-to-roll option, good for viscose and mixed fabrics.

Industrial Digital Textile Printing Machine – Large scale digital fabric printing machine, high capacity.

High Speed Digital Textile Printing Machine – Designed for very high throughput, ideal for bulk.

Cotton Fabric Digital Textile Printer Automatic Grade – Focus on cotton fabric with automation.

Silk Digital Textile Printing Machine For Fabric – Specialized for silk and fine fabrics.

Fabric Automatic Digital Textile Printing Machine – Full automation, minimal manual intervention.

Textile Printing Machinery – Broader machine category for flexibility.

Durable Digital Textile Printers – Emphasis on durability and long-term use.

How to Choose the Right “Best Fabric Printing Machine | HGS Machines” for You

Given the range, how do you pick the machine that suits your business?

A. Understand Your Fabric Types & Volume

What fabrics do you print most (cotton, polyester, silk, viscose, blends)?

Do you need short runs or large rolls?

For example, if you deal in cotton and small runs, a machine like the “Cotton Fabric Digital Textile Printer Automatic Grade” may be best.

If you print large volumes continuously, you might go for a 32-head model (Blaze) or high speed machine. HGS lists 32-head “Blaze” as top-end.

B. Print Quality vs Speed Trade-Off

Higher head count (16-head, 32-head) gives higher speed but usually higher investment.

If quality is priority (for premium fashion or home décor), ensure machine has advanced printheads like Ricoh Gen6. HGS mentions that.

If volume is priority (bulk fabrics for export, home textiles), speed matters more.

C. Ink & Fabric Compatibility

Does the machine support the ink types you use: reactive, pigment, sublimation? HGS covers pigment based and sublimation.

Does the machine support your fabric width? Many listings show widths like 1650 mm.

Ensure post-treatment (fixing, washing) requirements match your workflow.

D. Automation & Workflow Integration

Does your factory need automatic feeding, roll change, tension controls, fabric alignment?

HGS claims automation features.

The less manual intervention, the less downtime and error, hence better ROI.

E. Service & Support

Make sure there is local service presence, spares, trained operators.

HGS emphasises training and on-call service.

This becomes more important for machines running 24/7.

F. Cost & ROI Considerations

Evaluate not just machine cost but ink consumption, energy use, fabric wastage, operator labour.

Big machines cost more but can pay off if volume justifies.

HGS indicates goal of “economical price” and helping with cost reduction.

Real-World Use Case: Why Businesses Choose HGS

Here are scenarios where choosing the best fabric printing machine | HGS Machines adds value:

Fashion Brand: A brand launching a seasonal capsule collection may need high-detail, multiple colour prints on silk or viscose. They may pick the 8-head or 16-head HGS model for flexibility and detail.

Home Furnishing Manufacturer: Needs wide-width printing on cotton/linen at high speed for curtains, bedsheets. They pick a 32-head roll-to-roll HGS machine to match volume.

Start-Up Sample/Customization Unit: A small unit doing short runs or custom prints may invest in a smaller HGS machine focusing on cotton or blends.

Export Unit: High volume orders needing 24/7 run time; picks top-end HGS machine, ensures service support and automation to minimise downtime.

In each case, the keyword “best fabric printing machine | HGS Machines” aligns because the buyer is looking for reliability, capacity, fabric fit, support — and picks HGS for the brand strength.

Pros & Cons: What You Gain and What to Watch

? Pros

Wide range of machine configurations (4-head to 32-head) means you can scale.

Support for multiple fabric types and ink technologies (direct, pigment, sublimation).

Emphasis on automation and print quality — helping reduce waste and increase output.

After-sales support and training included — fewer risks when investing.

?? Cons / Things to Watch

The cost of high-head count machines is significant; budget must match scale.

While HGS offers broad range, you must check local availability of service/spares in your region.

Fabric handling, pretreatment or finishing may still require manual operations depending on your setup.

Machine alone doesn’t guarantee success; inks, workflow, staff training matter.

Checklist: Is This the Right Investment for You?

Use this checklist before you commit:

Does this “fabric printing machine | HGS Machines” support the fabric types you work with?

Is its width, head count and speed aligned to your production volume?

Does it support the ink type(s) you use (reactive, pigment, sublimation)?

What is the total cost of ownership (machine cost + ink + consumables + maintenance)?

What support and training does HGS provide locally?

Does your facility have space, power, ventilation required for that machine?

Are your workflow, digital design file processes ready to handle this machine’s capability?

What is the expected ROI: how many metres per day? How many hours of operation?

Are you ready for upgrade in fabrics, designs or volume in next 3-5 years?

If the answer to most is “yes”, you are on track to choosing the best fabric printing machine | HGS Machines for your needs.

Frequently Asked Questions (FAQ)

About the Best Fabric Printing Machine | HGS Machines

Q1. What makes HGS Machines the best fabric printing machine brand?

A: HGS Machines is considered one of the best because it combines high-speed digital printing with consistent quality across different fabrics. The best fabric printing machine | HGS Machines offers advanced printheads, automation, and durable build quality. They also provide after-sales service and training, which ensures long-term reliability.

Q2. Which fabrics can I print on with HGS Machines?

A: The best fabric printing machine | HGS Machines is designed for multiple fabric types — including cotton, silk, polyester, viscose, linen, and blends. You can choose between pigment-based, reactive, or sublimation ink systems depending on your fabric and design needs.

Q3. What is the price range of HGS fabric printing machines?

A: The price range for HGS fabric printing machines generally starts around ?18–20 lakhs for entry-level models and can go up to ?4 crores for high-speed, industrial-grade machines. The cost depends on the printhead count (like 4-head, 8-head, 16-head, or 32-head) and automation features.

Q4. How do I choose the best fabric printing machine for my business?

A: To select the best fabric printing machine | HGS Machines, consider your:

Production volume (small, medium, or industrial scale)

Fabric types (cotton, silk, polyester, etc.)

Ink preferences (pigment, reactive, sublimation)

Required speed and print quality

Available budget and space

HGS Machines provides guidance to help you pick a model that suits your exact business setup.