In today’s textile and apparel industry, precision, speed, and quality define success. The evolution from manual printing to digital technology has completely transformed how fabrics are designed and produced. Among the most impactful innovations is the industrial fabric printer, a machine that combines automation, accuracy, and creativity to produce stunning fabric designs at industrial scale.

If you’re a textile manufacturer, fashion brand, or printing startup, understanding what an industrial fabric printer is, how it works, and how to choose the right one can give your business a serious competitive advantage. In this detailed guide, we’ll explore everything you need to know — from printing technology to benefits, applications, and buying tips.

1. What Is an Industrial Fabric Printer?

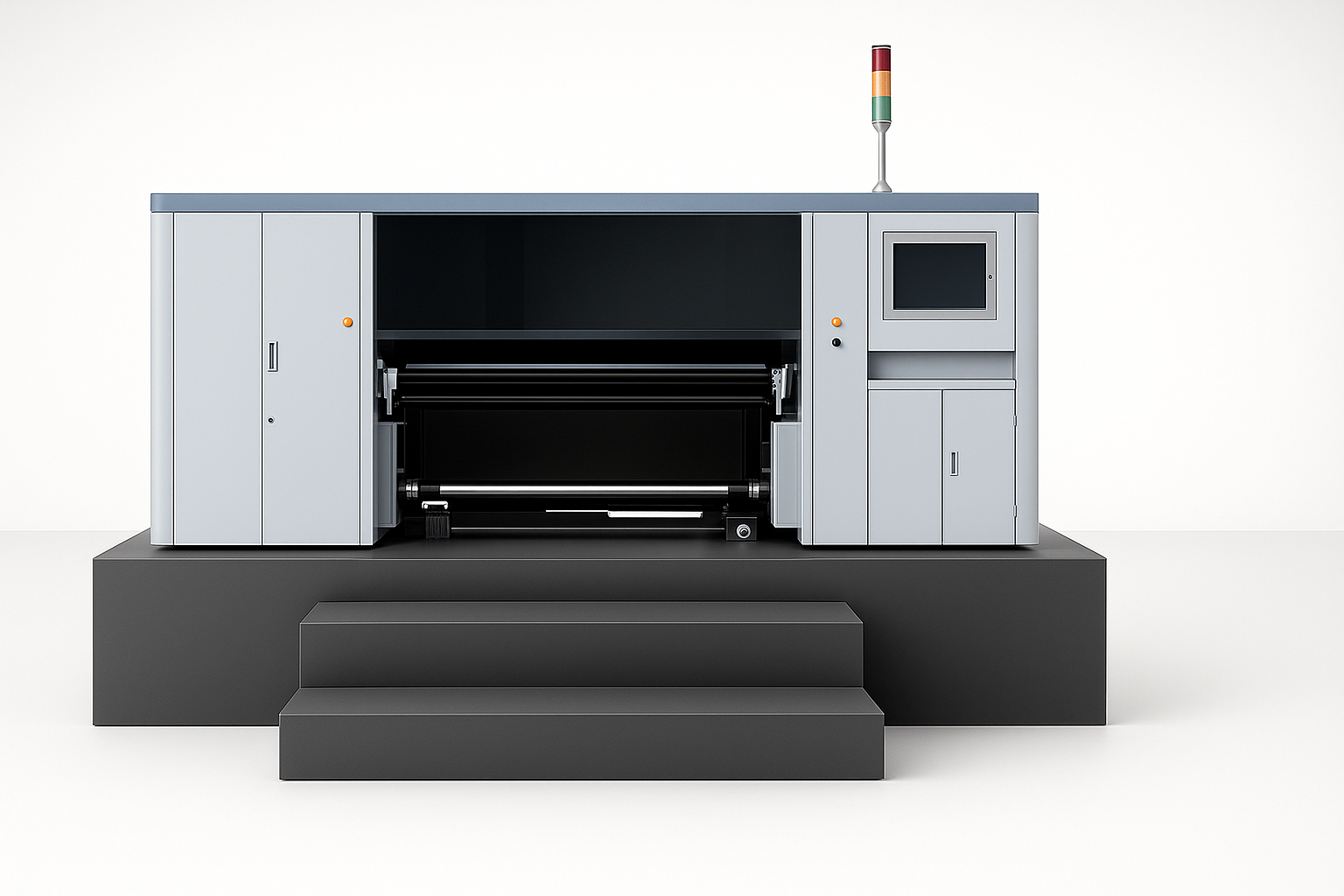

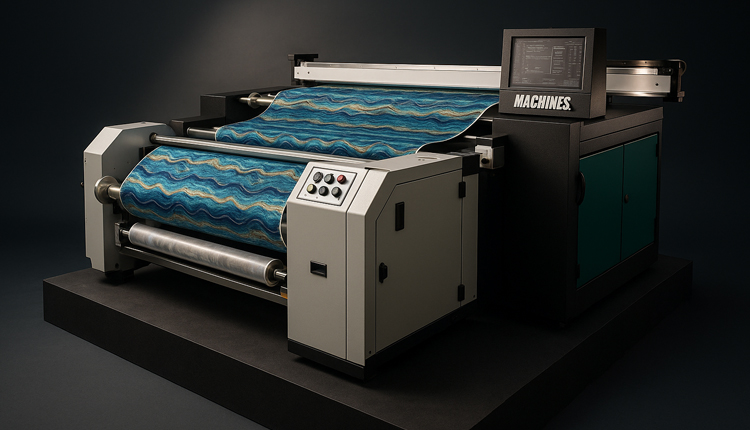

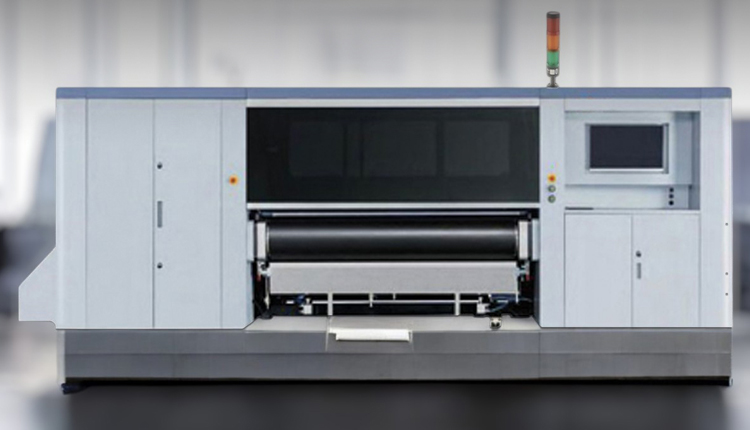

An industrial fabric printer is a high-performance machine designed to print directly on large rolls of textile material with precision and consistency. Unlike small desktop printers or traditional screen printing, an industrial fabric printer uses advanced digital printing technology to apply inks directly onto fabrics such as cotton, silk, polyester, linen, and rayon.

These machines are built for mass production — capable of printing hundreds of meters of fabric per hour while maintaining color consistency and sharpness. An industrial fabric printer can handle continuous operation, multiple color layers, and complex designs without human error.

In short, if your goal is to produce high-quality prints on fabric at scale, you need an industrial fabric printer.

2. How an Industrial Fabric Printer Works

Understanding how an industrial fabric printer operates helps you appreciate its precision and efficiency.

Here’s a simplified breakdown:

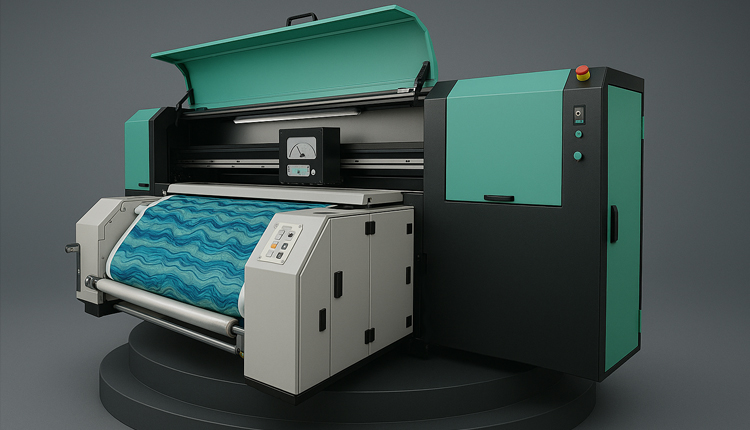

Design Creation – The process begins with a digital design file (created in software like Photoshop or Illustrator).

Fabric Preparation – The fabric is pre-treated to ensure ink absorption and color fastness.

Printing Process – The industrial fabric printer uses specialized printheads (usually Epson, Ricoh, or Kyocera) that spray micro-droplets of dye or pigment inks onto the fabric.

Drying & Fixation – The printed fabric passes through heat or steam chambers to fix the color permanently.

Finishing – The final step may include washing, stretching, or calendaring to achieve the desired texture and finish.

Every stage is optimized for industrial production, where uptime, accuracy, and consistency matter the most.

3. Types of Industrial Fabric Printers

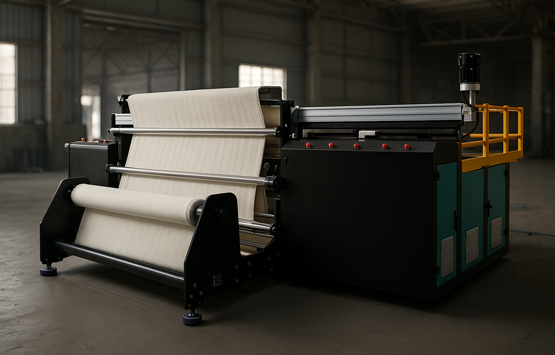

The market offers several types of industrial fabric printers, depending on ink type and fabric compatibility.

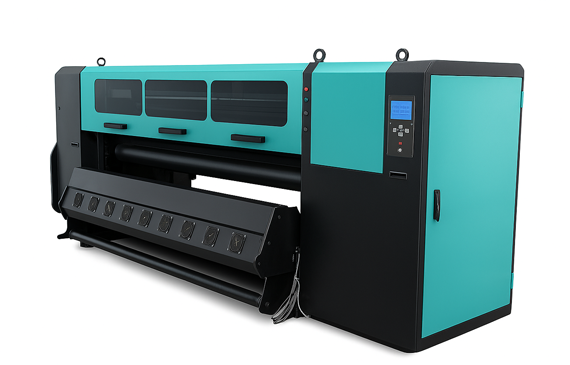

a. Dye Sublimation Industrial Fabric Printer

Used mainly for polyester fabrics, this printer transfers dye from paper onto fabric using heat. Ideal for sportswear, banners, and home textiles.

b. Direct-to-Fabric (DTF) Industrial Fabric Printer

Prints directly on cotton, silk, viscose, or blended fabrics using reactive, pigment, or acid inks. Perfect for apparel, scarves, and upholstery.

c. UV Industrial Fabric Printer

Uses UV-curable inks for printing on coated or synthetic materials. It’s suitable for custom applications and signage.

d. Hybrid Industrial Fabric Printer

A versatile option that can print both transfer and direct, giving flexibility for various fabric types.

Each industrial fabric printer type serves different industries, so it’s important to choose based on your production material and end-use.

4. Why the Industrial Fabric Printer Is a Game-Changer

The traditional methods of textile printing like rotary or screen printing are time-consuming, require high setup costs, and limit design flexibility. In contrast, the industrial fabric printer brings a digital revolution that redefines efficiency and creativity.

Key advantages include:

1. High-Speed Production

Modern industrial fabric printers can print hundreds of square meters per hour — ideal for bulk textile manufacturers.

2. Zero Screen Setup

No need for screens or templates. The digital file is uploaded directly, reducing setup time drastically.

3. Unlimited Design Possibilities

Complex, multi-color patterns and photographic prints can be produced easily with an industrial fabric printer.

4. Eco-Friendly Printing

Most industrial fabric printers use water-based inks and produce minimal waste, making them environmentally friendly.

5. Lower Cost per Meter

Once installed, the running cost of an industrial fabric printer is lower than traditional methods, especially for short runs or customized designs.

6. Consistent Quality

With automated calibration and advanced printheads, an industrial fabric printer ensures consistent color output across large volumes.

7. Easy Customization

Brands can offer personalized designs with on-demand production using industrial fabric printers — no overstock or waste.

5. Applications of Industrial Fabric Printers

The versatility of the industrial fabric printer makes it essential across multiple industries:

Whether for bulk production or niche applications, the industrial fabric printer serves as a bridge between creativity and commercial scalability.

6. Choosing the Right Industrial Fabric Printer

Before buying an industrial fabric printer, consider these factors:

a. Type of Fabric

Different printers are optimized for specific fabrics. For example, dye-sublimation for polyester, reactive ink for cotton, and pigment ink for mixed fabrics.

b. Printing Volume

If you produce 24/7, choose an industrial fabric printer built for continuous operation with durable components.

c. Print Quality

Check the DPI (dots per inch) resolution, number of printheads, and ink droplet size. Higher precision means sharper, more detailed prints.

d. After-Sales Support

Look for companies offering installation, training, and quick technical service. Industrial fabric printers are heavy machines that need reliable maintenance.

e. Cost and ROI

Compare not just the purchase price, but also ink costs, energy consumption, and service intervals. A slightly higher-priced industrial fabric printer with lower running costs may give better ROI.

f. Software Compatibility

Ensure the printer supports standard design software and RIPs for color management and workflow automation.

7. Maintenance Tips for Industrial Fabric Printers

Proper maintenance ensures long-term performance and print quality. Here’s how to care for your industrial fabric printer:

Daily Head Cleaning: Prevents ink clogging and maintains print consistency.

Proper Ventilation: Avoid humidity and dust around the printer.

Regular Calibration: Ensures alignment accuracy and color consistency.

Use Genuine Inks: Avoid third-party inks that may damage the printhead.

Scheduled Servicing: Always follow manufacturer’s recommended service intervals.

Well-maintained industrial fabric printers can last several years and maintain production quality even under heavy use.

8. Future of Industrial Fabric Printing

The future of the industrial fabric printer industry is bright and innovation-driven. As sustainability and customization become priorities, digital textile printing will dominate global manufacturing.

Trends to watch:

Waterless Printing Technology to reduce environmental impact.

Smart Inks that adapt to various textures.

AI-Powered Printing Systems that optimize ink usage and detect defects automatically.

Hybrid Industrial Fabric Printers capable of printing multiple fabric types in one run.

As demand for fast, flexible, and sustainable fabric production grows, the industrial fabric printer will continue to shape the future of textile manufacturing.

9. Conclusion

An industrial fabric printer is more than a machine — it’s the foundation of modern textile innovation. Whether you run a small boutique printing business or a large manufacturing unit, adopting this technology opens doors to creativity, scalability, and efficiency.

By understanding the types, benefits, and maintenance of an industrial fabric printer, you can make a well-informed investment that transforms your production workflow.

If you’re planning to expand your textile business, explore advanced industrial fabric printers from reputed manufacturers, and start producing high-quality, vibrant fabrics that stand out in the market.

The future of fabric printing is digital — and it starts with the right industrial fabric printer.

FAQs

1. What is an industrial fabric printer?

An industrial fabric printer is a digital machine designed for large-scale printing on fabrics like cotton, polyester, and silk with high precision.

2. How fast can an industrial fabric printer print?

Depending on the model, an industrial fabric printer can print 100–500 square meters of fabric per hour.

3. Which fabrics can be printed using an industrial fabric printer?

Cotton, polyester, silk, rayon, viscose, and blended fabrics are compatible with most industrial fabric printers.

4. Is digital fabric printing eco-friendly?

Yes, modern industrial fabric printers use water-based inks that reduce chemical waste compared to traditional printing methods.

With proper maintenance, an industrial fabric printer can operate efficiently for 5–10 years or more.