A textile printer has become one of the most important machines for modern fabric businesses. From small boutiques to large manufacturing units, everyone wants a textile printer that gives fast printing, low running cost, and clear designs. The rise in custom fashion, digital printing, and short-run production has made the textile printer a must-have machine in the industry.

If you are planning to grow your textile business, upgrade your printing setup, or understand how a textile printer works, this detailed guide will help you. The aim is to explain everything in simple language—no complicated terms, only clear information.

What Is a Textile Printer?

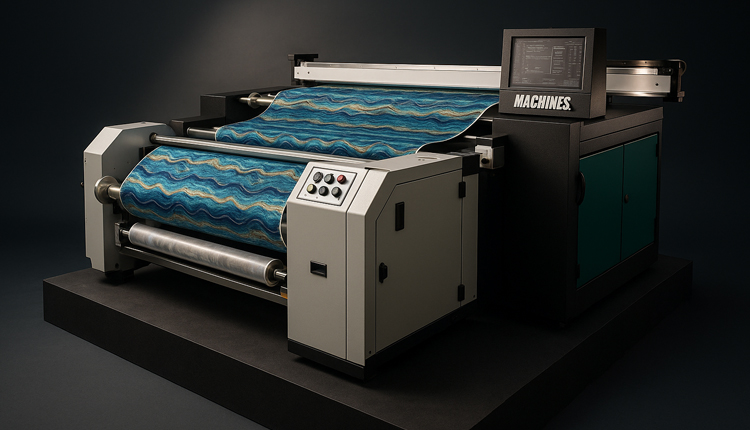

A textile printer is a machine that prints designs, logos, colors, and patterns directly on fabric. Unlike old methods where plates and screens were needed, a digital textile printer can print high-quality designs directly from a computer.

Today, a digital textile printer is used for:

T-shirts

Sarees

Dress materials

Curtains

Bedsheets

Upholstery

Corporate fabric

Fashionwear and sportswear

The textile printer saves time, reduces waste, and delivers clean results without heavy manpower.

Why the Textile Industry Is Shifting to Digital Textile Printers

The demand for digital textile printer technology has grown because:

1. Customers want custom prints

Everyone needs personalized fashion. A textile printer makes it easy to print orders in small or large quantities.

2. Faster production

A textile printer prints hundreds of meters in hours, helping businesses meet deadlines.

3. Better color quality

Modern textile printers offer high resolution, sharp edges, and bright colors.

4. Lower operational cost

No plates, no screens, no long setup time. A textile printer reduces cost per print.

5. Eco-friendly options

Digital textile printers use less water and ink compared to traditional printing.

Types of Textile Printers

Understanding the types will help you pick the best textile printer for your unit.

1. DTG (Direct-to-Garment) Textile Printer

Best for T-shirts and cotton garments.

Prints directly on the cloth surface.

Ideal for short-run custom orders.

2. DTF (Direct-to-Film) Textile Printer

Prints on film and transfers to fabric.

Suitable for cotton, polyester, blends.

Very popular due to low cost.

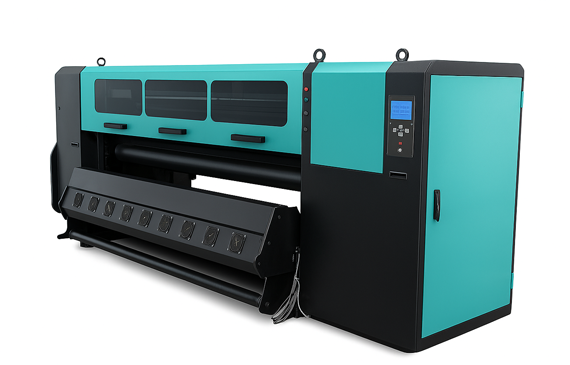

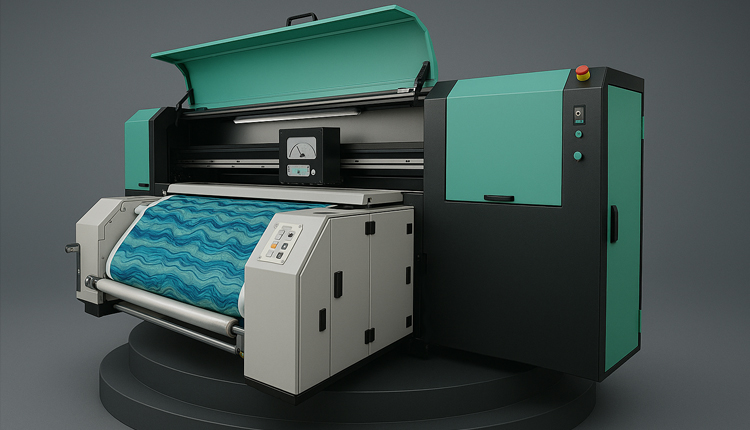

3. Sublimation Textile Printer

Used for polyester fabrics.

Common in sportswear, banners, and corporate clothing.

Bright colors, smooth finish.

4. UV Textile Printer

Used for mixed materials and promotional fabrics.

Fast curing technology.

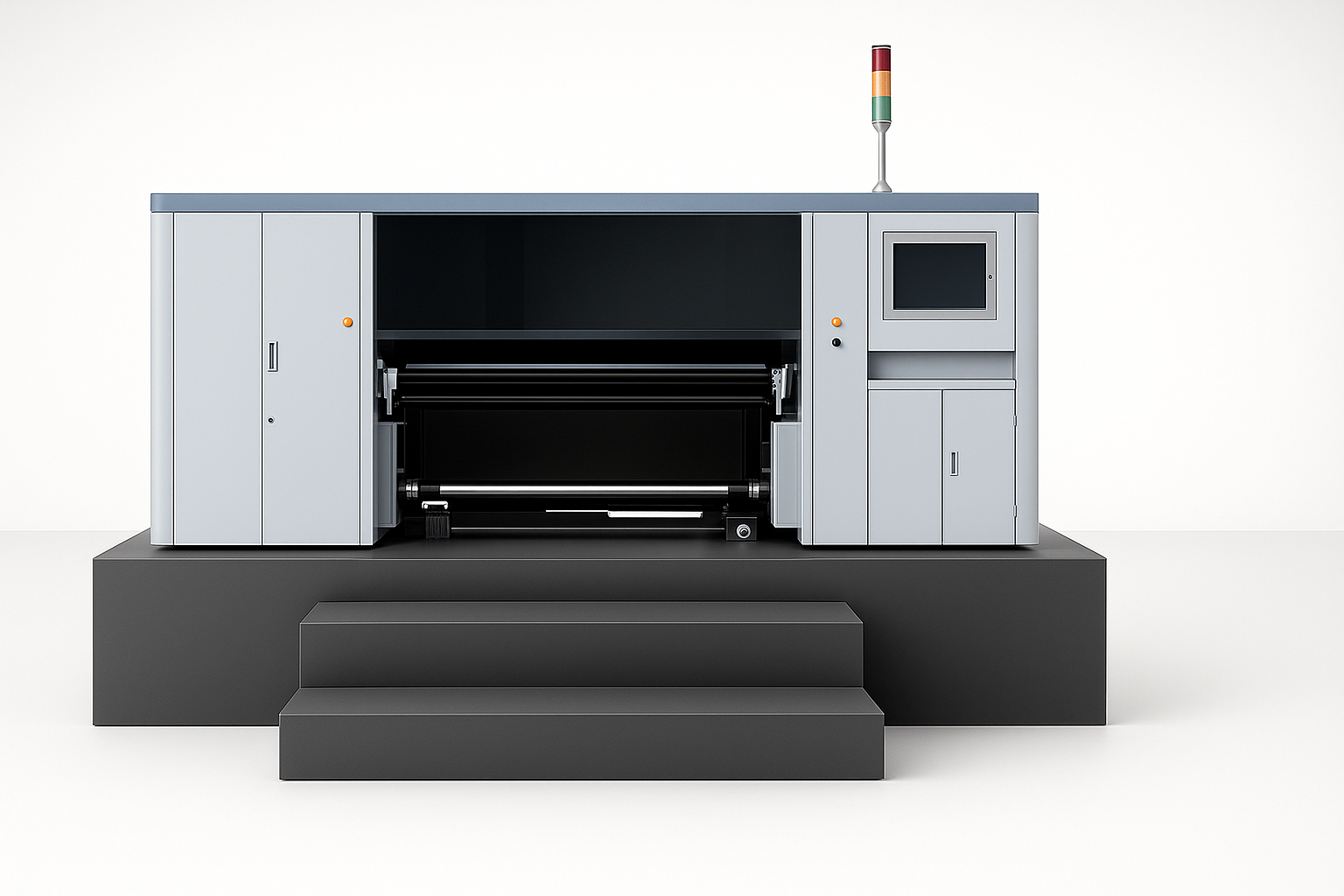

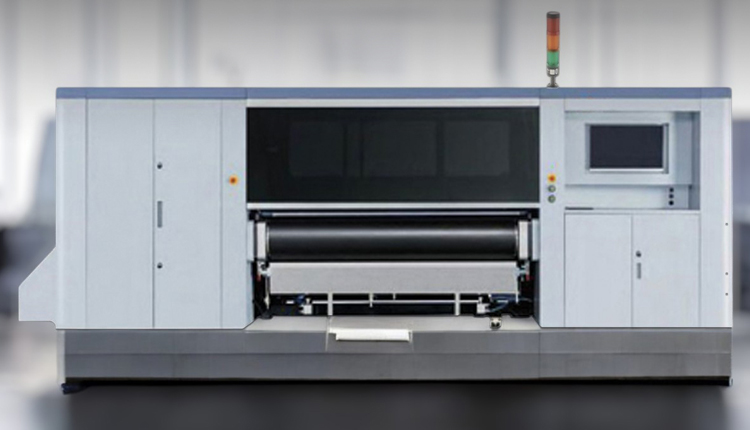

5. Industrial Textile Printer

Large-scale printing for manufacturers.

High speed + durability.

Each textile printer type offers its own benefits, but digital machines are becoming the top choice across the industry.

How a Textile Printer Works: Step-by-Step

Even though the technology is advanced, the process is simple:

Design creation

A design is made on software like Photoshop, CorelDRAW, or Illustrator.Fabric preparation

The fabric may be pre-treated depending on the type of textile printer.Printing

The textile printer prints the exact colors and design on the fabric.Drying or curing

The prints are heated or steamed for long-lasting quality.Final check

The fabric is inspected for color accuracy and clarity.

A textile printer reduces error and gives consistent output every time.

Top Features to Look for in a Textile Printer

When buying a textile printer, keep these points in mind:

1. Print resolution

Higher resolution gives better design clarity.

2. Ink type

Choose between pigment, sublimation, reactive, or DTF inks based on fabric type.

3. Print width

Wider printers help in large-scale production (bedsheets, sarees, banners).

4. Speed

Higher speed = more profits for large businesses.

5. Maintenance requirements

A textile printer with low maintenance saves time and money.

6. Support and parts availability

Choose brands that offer local support and easy spare parts.

Benefits of Using a Textile Printer in Your Business

1. Lower cost per print

You save more on inks, labor, and setup compared to screen printing.

2. Faster delivery

You can complete orders in hours instead of days.

3. Unlimited design possibilities

Any design you imagine can be printed.

4. High accuracy

Colors come out clean, sharp, and aligned.

5. No screen or plate cost

This is a big advantage in small-batch orders.

6. Works on multiple fabrics

A textile printer can print on cotton, polyester, blends, silk, rayon, and more.

Industries That Use a Textile Printer

A textile printer is used in many industries, including:

Fashion and apparel units

Home furnishing manufacturers

Boutique printing units

Sportswear brands

Promotional product companies

Textile export houses

Corporate merchandise makers

Fabric wholesalers

The demand for a textile printer is increasing every year because more businesses need fast and custom printing.

Digital Textile Printer vs Traditional Printing

Digital technology clearly gives more advantages for today’s market.

How to Choose the Best Textile Printer for Your Needs

When selecting a textile printer, ask yourself:

1. What fabrics do I print?

Cotton ? DTG

Polyester ? Sublimation

Mixed fabrics ? DTF

Large rolls ? Industrial printer

2. What is my order volume?

Small batches ? Desktop textile printer

Large batches ? Industrial textile printer

3. What is my budget?

Choose a textile printer that gives the best output within your cost.

4. Do I need multi-color or special effects?

Some printers support white ink, neon ink, and special shades.

5. What after-sales service is available?

Always pick a brand that provides strong support and quick service.

Maintenance Tips for Longer Life of Your Textile Printer

A textile printer lasts longer with simple daily care:

Clean print heads regularly

Use original ink

Keep the machine dust-free

Run a test print daily

Check humidity and temperature

Lubricate moving parts

Update software regularly

Store fabric properly

These simple steps keep your textile printer running smoothly.

Cost of a Textile Printer in India

The price depends on size, brand, and printing technology.

Entry level textile printer: ?1,00,000 – ?2,50,000

DTG textile printer: ?2,00,000 – ?6,00,000

DTF textile printer: ?1,50,000 – ?5,00,000

Sublimation textile printer: ?3,00,000 – ?10,00,000

Industrial textile printer: ?12,00,000 – ?30,00,000+

Businesses choose based on volume and long-term goals.

Future of Textile Printer Technology

The textile printer industry will continue growing due to:

Demand for custom fashion

Faster delivery requirements

Eco-friendly printing

Lower cost of inks and machines

Rise of online clothing shops

Higher export demand

Automation and AI-based color correction will make textile printers even more efficient.

Conclusion

A textile printer is no longer optional—it is the backbone of modern textile production. Whether you're a small boutique, a growing fashion brand, or a large manufacturing unit, a textile printer gives you speed, quality, and flexibility. It reduces cost, boosts business performance, and ensures you always stay ahead in a competitive market.

If you want to grow your printing business in 2025, investing in the right textile printer is one of the smartest decisions you can make.

FAQs

1. What is a textile printer used for?

A textile printer is used to print designs directly on fabric with high quality.

2. Which textile printer is best for cotton?

A DTG textile printer is best for printing on cotton.

3. Is digital textile printing costly?

Digital printing is economical for small and large orders.

4. Can a textile printer print on polyester?

Yes, sublimation and DTF textile printers work well on polyester.

A well-maintained textile printer can last 5–10 years.