Fabric Printing Machine Cost: How Much Should You Expect to Pay?

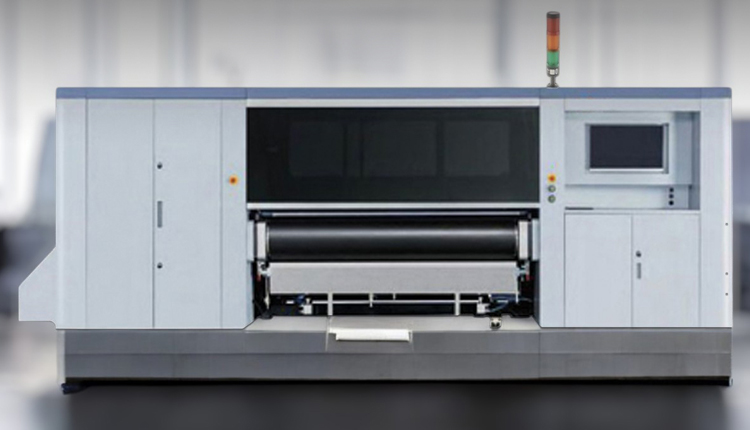

The textile industry has changed dramatically in recent years. Businesses are no longer limited to traditional screen printing; digital fabric printing machines now allow precise, fast, and cost-effective production. If you’re exploring textile printing for your business, one of the first questions you’ll ask is: “What is the fabric printing machine cost?”

In this guide, we’ll break down the factors that influence the fabric printing machine cost, types of machines available, and tips to choose the right option for your needs.

Why Understanding Fabric Printing Machine Cost Matters

Investing in a fabric printing machine is not cheap. The fabric printing machine cost varies depending on technology, capacity, brand, and additional features. Understanding the costs upfront helps businesses:

Budget effectively.

Choose the right machine for their production volume.

Avoid overpaying for features they don’t need.

Plan for operational costs like ink, maintenance, and consumables.

Whether you are setting up a small-scale printing business or upgrading to high-end production, knowing the fabric printing machine cost is crucial.

Factors Affecting Fabric Printing Machine Cost

Several factors influence the fabric printing machine cost.

1. Type of Printing Technology

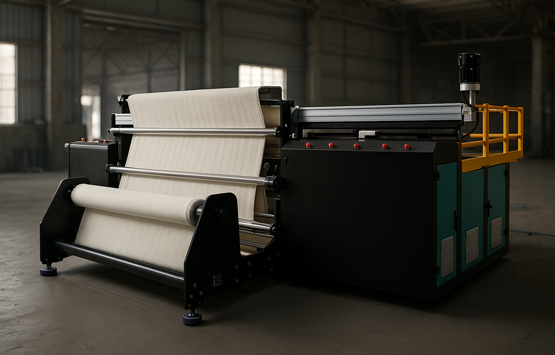

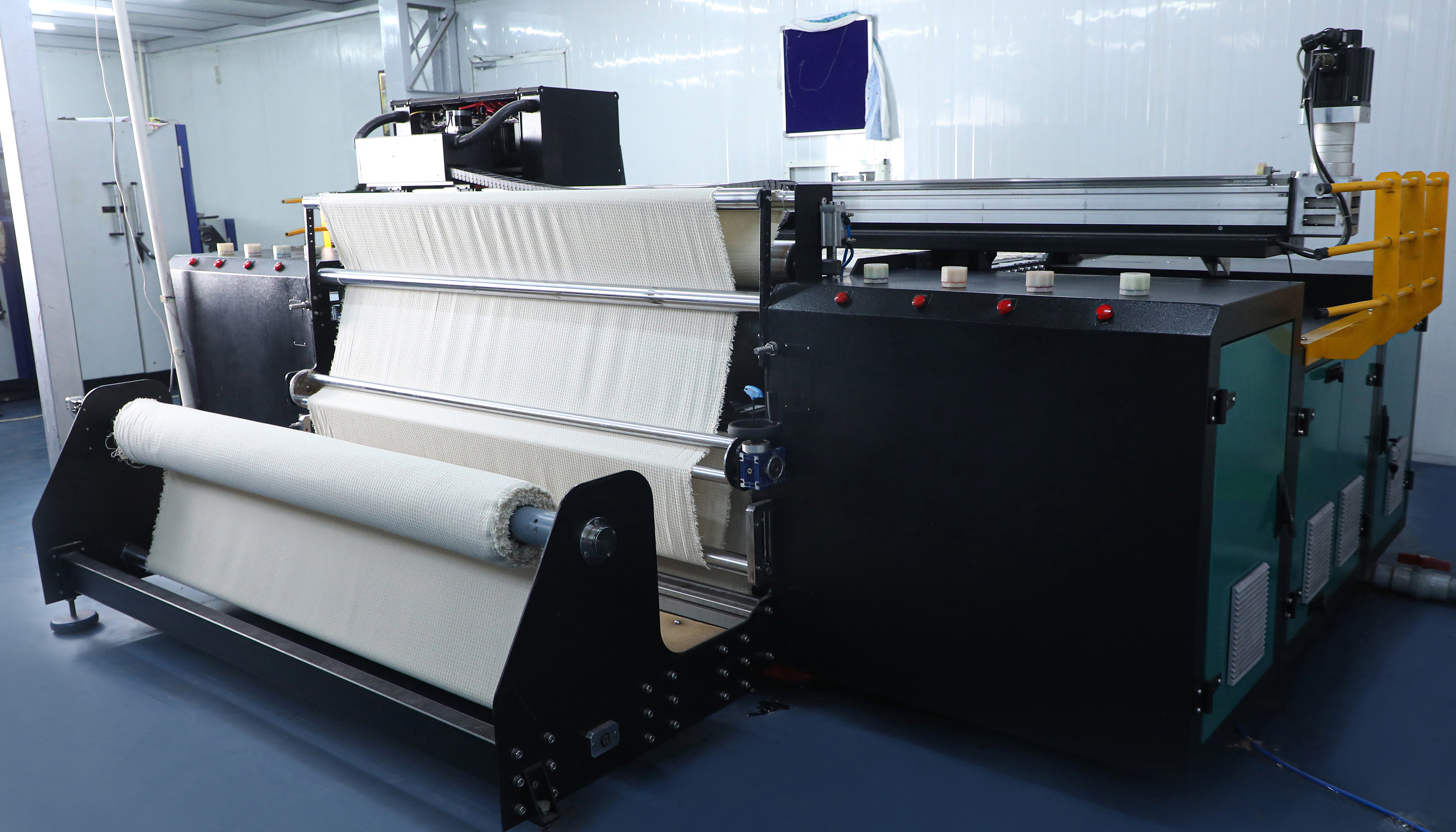

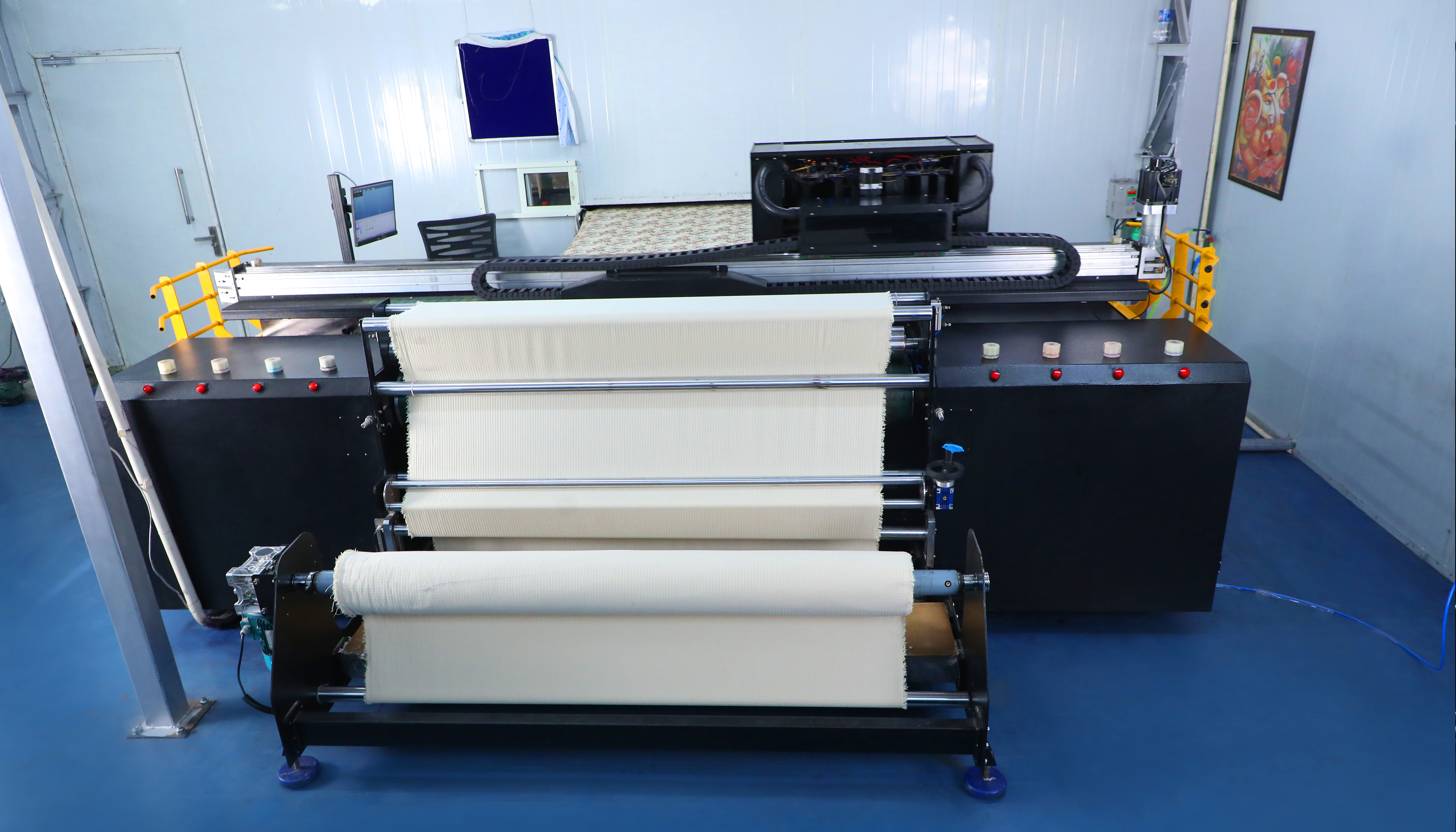

Direct-to-Fabric Printers: Use single-pass or multi-pass digital printing. Higher speed single-pass printers usually have a higher fabric printing machine cost but save time and labor.

Pigment Printing Machines: These printers are suitable for cotton and natural fibers. They often have a lower upfront fabric printing machine cost but may have higher running costs due to ink usage.

Sublimation Printers: Ideal for polyester fabrics, these machines have a moderate fabric printing machine cost and are popular for sportswear and fashion.

2. Printing Capacity

Higher capacity machines that can print more fabric per hour generally have a higher fabric printing machine cost. If you plan to scale production, investing in a high-capacity machine can be cost-effective in the long run.

3. Number of Print Heads

Machines with multiple print heads produce faster and more detailed prints. For example:

4-head machines: lower fabric printing machine cost, suitable for small businesses.

8-16 head machines: moderate fabric printing machine cost, good for medium-scale production.

32-head or more: high fabric printing machine cost, ideal for large industrial production.

4. Brand and Quality

Reputed brands like HGS Machines, Epson, and Mimaki may charge a higher fabric printing machine cost. However, their machines offer reliability, better service, and longer life. Lesser-known brands may be cheaper but can have higher maintenance costs.

5. Automation and Features

Automated feeding, tension control, and alignment systems increase efficiency but also raise the fabric printing machine cost. Machines with advanced features like automatic color calibration and multi-layer printing will cost more but reduce human error and fabric waste.

Estimated Fabric Printing Machine Cost

The fabric printing machine cost varies widely depending on the factors above:

Note: Prices are indicative and may vary based on location, brand, import taxes, and service packages.

Operational Costs to Consider

Buying a machine is just the first step. The total fabric printing machine cost includes operational expenses:

Ink: Water-based or pigment inks; costs vary per liter.

Maintenance: Cleaning, spare parts, and calibration.

Electricity: High-speed machines may consume more power.

Consumables: Fabric rolls, printing beds, and protective sheets.

Labor: Operators and technicians.

Considering these costs helps calculate the real fabric printing machine cost per meter of fabric, which is critical for pricing your products.

Benefits of Investing in the Right Fabric Printing Machine

Though the fabric printing machine cost may seem high, the return on investment is substantial:

Faster Production: High-capacity machines print large volumes quickly.

Better Quality: Consistent colors, sharper designs, and smooth gradients.

Lower Waste: Digital printing reduces fabric and ink wastage compared to traditional methods.

Flexibility: Print multiple designs in small batches without changing screens.

Scalability: Upgradeable machines allow you to expand production as your business grows.

Tips to Reduce Fabric Printing Machine Cost

Choose Only Needed Features

Avoid paying extra for features you won’t use. Start small and upgrade later.Compare Brands

Don’t just go by price. Compare reliability, service, and training offered.Consider Refurbished Machines

Some reputable suppliers sell refurbished printers at lower fabric printing machine cost with warranties.Plan for Operational Efficiency

A slightly higher fabric printing machine cost for a machine with better speed and lower running costs can save money long-term.Negotiate Bulk Orders

If buying multiple machines, suppliers may offer discounts that reduce the effective fabric printing machine cost.

Where to Buy Fabric Printing Machines

You can find fabric printing machine cost estimates and machines from:

HGS Machines: Known for high-quality direct-to-fabric and pigment printers.

Epson and Mimaki: International brands offering reliable digital textile printers.

Local suppliers in industrial hubs like Delhi-NCR, Surat, and Tirupur.

Always verify warranties, service agreements, and training before purchasing.

Final Thoughts

Understanding the fabric printing machine cost is the first step to starting or expanding your textile printing business. Costs vary depending on machine type, capacity, print heads, brand, and features, but investing in the right equipment ensures better quality, higher productivity, and long-term profitability.

Whether you are a startup looking for an entry-level printer or an industrial unit needing a high-capacity machine, calculate the total fabric printing machine cost including operational expenses to make a smart decision. With careful planning, your investment will pay off in efficiency, quality, and customer satisfaction.

FAQ

What is fabric printing machine cost?

The price of a fabric printing machine varies by type, capacity, and brand, ranging from 6 lakhs to 90 lakhs INR.What factors affect fabric printing machine cost?

Technology, print heads, automation, brand, and production capacity influence the cost.Are there operational costs besides the machine price?

Yes—ink, maintenance, electricity, consumables, and labor add to the total cost.Can I buy a lower-cost machine for small-scale printing?

Yes, entry-level 4-head machines are suitable for startups and small businesses.Do higher-cost machines offer benefits?

Higher-cost machines provide faster production, better quality, lower waste, and scalability.

Reputable suppliers include HGS Machines, Epson, Mimaki, and local industrial hubs like Delhi-NCR, Surat, and Tirupur.