High Speed Textile Printer: A Complete Guide for Businesses

Textile printing has changed a lot in the last two decades. From slow traditional methods to advanced machines, the industry has moved toward speed, accuracy, and cost-effectiveness. Among all the innovations, the high speed textile printer is one of the biggest game changers.

Whether you are a small business or a large textile manufacturer, investing in a high speed textile printer can improve your production capacity, lower costs, and help you meet customer demands faster. In this guide, we will cover everything you need to know about high speed textile printers, their features, benefits, uses, and buying tips.

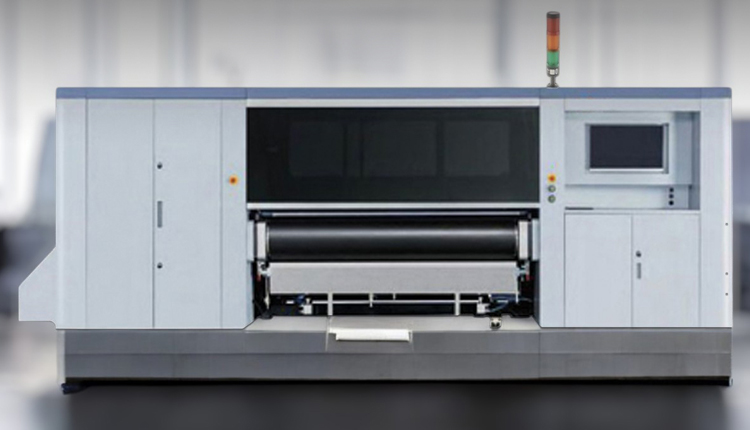

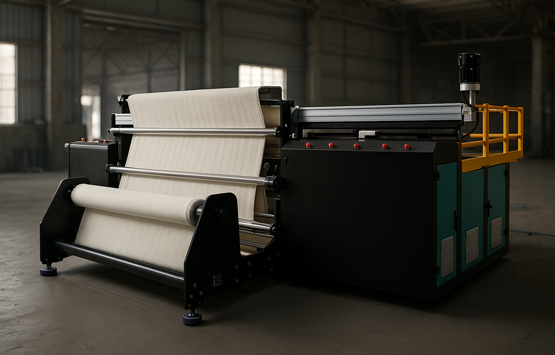

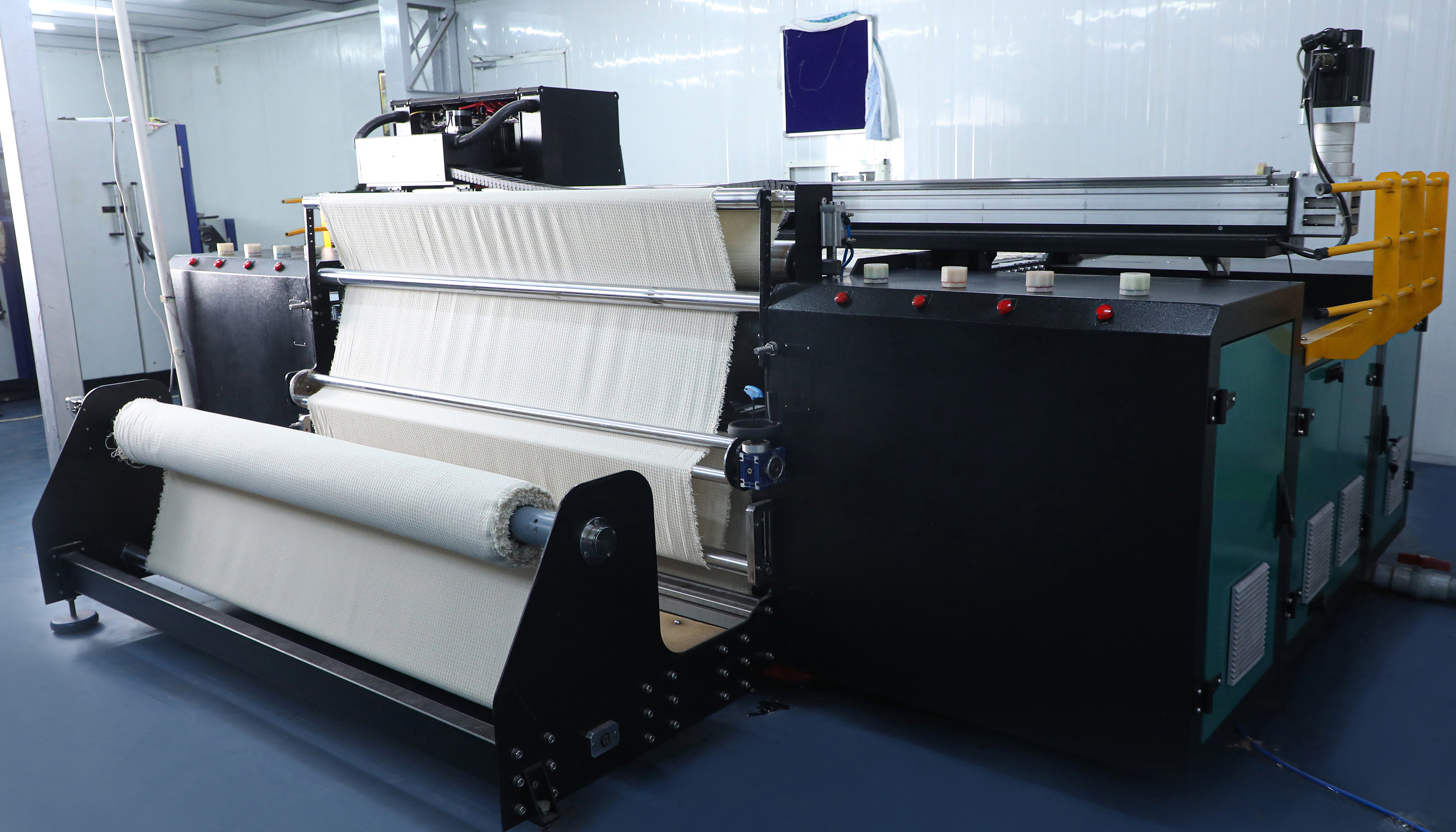

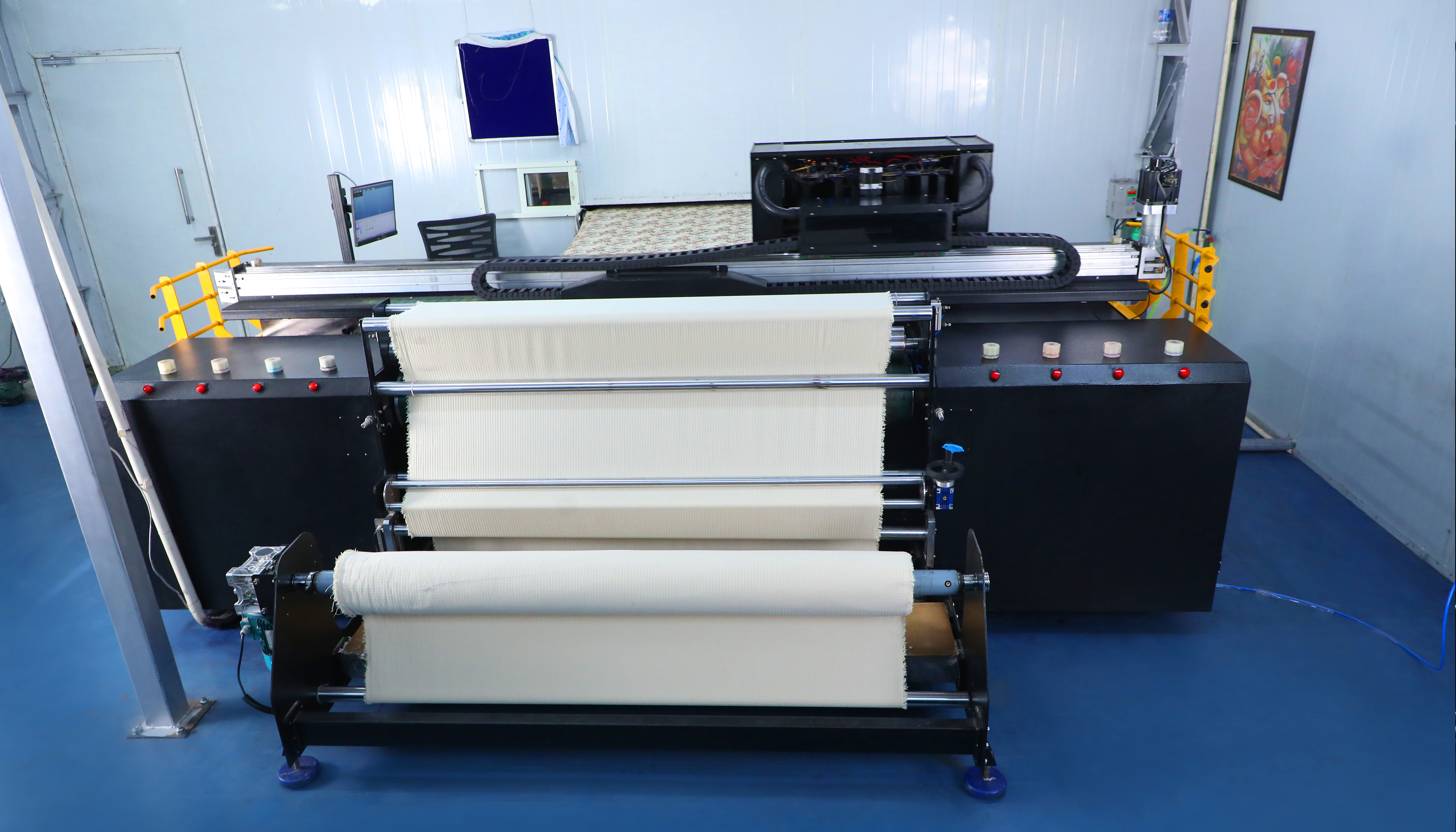

What is a High Speed Textile Printer?

A high speed textile printer is a digital printing machine designed to print designs directly onto fabrics at a fast rate. Unlike traditional screen printing, which is slow and requires manual setup, the high speed textile printer uses advanced printheads and digital technology to handle large volumes quickly.

These printers are used by businesses that need high-quality prints on cotton, polyester, silk, rayon, linen, and blended fabrics. The key factor is speed — many high speed textile printers can print hundreds of meters of fabric in a single day.

Why Speed Matters in Textile Printing

The textile industry works on deadlines. Fashion brands, exporters, and garment manufacturers often need bulk fabric in limited time. A high speed textile printer reduces waiting time, improves efficiency, and allows businesses to take on more orders.

Faster production: More output in less time.

Lower labor cost: Fewer manual steps.

Quick design changes: You can switch from one design to another without delays.

Meeting market demand: Essential for fast fashion and e-commerce industries.

For businesses competing in India’s textile hubs like Surat, Tirupur, and Ludhiana, a high speed textile printer is no longer optional — it is a necessity.

Key Features of a High Speed Textile Printer

When choosing a high speed textile printer, you should look for the following features:

Advanced Printheads – The printheads control ink flow and directly affect speed and print quality.

Multiple Color Options – Most printers support CMYK and additional colors for detailed designs.

Wide Fabric Compatibility – Cotton, silk, polyester, blends, and more.

High Resolution – Even at fast speeds, a good high speed textile printer delivers sharp designs.

Durable Build – Heavy-duty frames for continuous industrial use.

User-Friendly Software – Easy design uploads and quick setup.

Energy Efficiency – Important for keeping running costs under control.

Continuous Ink Supply Systems – Reduces downtime and saves ink.

Benefits of Using a High Speed Textile Printer

Time Savings

The biggest benefit of a high speed textile printer is time. Jobs that took days with traditional printing can now be done in hours.Cost-Effective

While the initial investment is higher, the long-term savings in labor and production costs make it affordable.Flexibility

With a high speed textile printer, you can print short runs or bulk orders without wasting time.Consistent Quality

Unlike manual methods, digital textile printing maintains the same quality across the entire batch.Eco-Friendly

Many high speed textile printers use water-based inks that are safer for the environment.Easy Maintenance

Most modern machines are designed for simple cleaning and upkeep.

Applications of High Speed Textile Printers

A high speed textile printer can be used in several industries:

Fashion & Apparel – Printing designs on fabrics for clothing.

Home Furnishings – Curtains, upholstery, bed sheets, and cushion covers.

Sportswear – High-performance polyester fabrics with custom prints.

Scarves & Accessories – Silk and lightweight fabrics with sharp prints.

Custom Printing – Small businesses offering personalized t-shirts, bags, and more.

Choosing the Right High Speed Textile Printer

When buying a high speed textile printer, consider these points:

Your Production Needs

Small businesses may only need a mid-range printer.

Large factories should invest in industrial-scale high speed textile printers.

Type of Fabric

Pigment printers work well for cotton.

Sublimation printers are best for polyester.

Hybrid printers handle multiple fabrics.

Budget

Entry-level models are cheaper but slower.

Advanced machines cost more but produce higher volumes.

After-Sales Support

Service availability is critical. Always check if the company provides training, spare parts, and maintenance.

Total Cost of Ownership

Ink cost, energy usage, spare parts, and durability all matter. Don’t just look at the purchase price.

Common Questions About High Speed Textile Printers

1. Is a high speed textile printer suitable for small businesses?

Yes, many small businesses use compact models of high speed textile printers for custom orders and local sales.

2. How much does a high speed textile printer cost?

The cost depends on size, brand, and features. Entry-level printers are cheaper, while industrial high speed textile printers can be expensive but more productive.

3. Can a high speed textile printer print on cotton and polyester?

Yes, depending on the technology. Pigment-based high speed textile printers are good for cotton, while sublimation printers are best for polyester.

4. How long does a high speed textile printer last?

With regular maintenance, a good high speed textile printer can last 7–10 years.

5. Do I need trained staff to operate it?

Most modern machines are user-friendly, but training helps improve efficiency and reduce downtime.

Tips for Getting the Best Out of a High Speed Textile Printer

Use Quality Inks – Cheap inks may damage the printhead.

Regular Cleaning – Prevents clogging and ensures smooth operation.

Train Operators – Skilled staff can run the printer more efficiently.

Maintain Proper Environment – Avoid dust and humidity in the printing area.

Schedule Maintenance – Don’t wait for breakdowns; preventive care saves money.

Future of High Speed Textile Printing

The demand for high speed textile printers is only going to increase. With the rise of e-commerce, fashion brands, and personalized clothing, the need for faster, high-quality production is at an all-time high.

Manufacturers are now focusing on energy efficiency, automation, and AI-driven maintenance. Soon, high speed textile printers will not just be faster but also smarter, making textile printing even more cost-effective.

Final Thoughts

A high speed textile printer is an investment that pays for itself. Whether you are in fashion, home furnishing, or custom printing, this machine helps you keep up with demand, deliver high-quality results, and stay competitive.

By carefully choosing the right model, maintaining it well, and using it effectively, businesses can maximize output while reducing costs.

If you are planning to grow in the textile industry, a high speed textile printer is no longer an option — it is a must-have tool for success.

FAQs

What is a high speed textile printer?

A high speed textile printer is a digital machine that prints designs on fabric quickly and with high accuracy.Which fabrics can a high speed textile printer print on?

A high speed textile printer can print on cotton, polyester, silk, rayon, linen, and blended fabrics.Is a high speed textile printer good for small businesses?

Yes, compact models of high speed textile printers are suitable for small businesses with lower production needs.How much does a high speed textile printer cost?

The price of a high speed textile printer varies based on size, brand, and features.

With proper maintenance, a high speed textile printer can last 7–10 years.