The textile industry is growing fast, and at the heart of it is the textile fabric printing machine. From fashion houses to home furnishing brands, everyone needs high-quality printed fabrics. A textile fabric printing machine helps businesses create designs directly on fabric with speed, precision, and lower costs.

If you are planning to buy or upgrade a textile fabric printing machine, this guide will help you understand its types, uses, benefits, and things to consider before making a purchase.

What is a Textile Fabric Printing Machine?

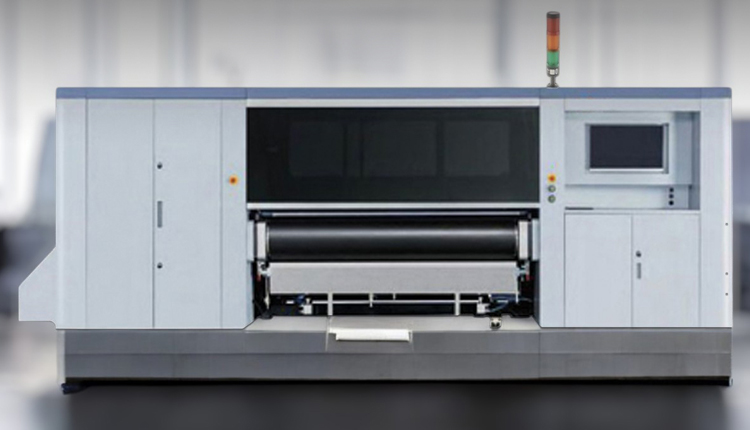

A textile fabric printing machine is a machine that prints patterns, designs, and colors directly onto different kinds of fabrics. Instead of traditional block or screen printing, this advanced machine uses digital technology or rotary systems to produce sharp and detailed prints.

Today, many businesses prefer a digital textile fabric printing machine because it allows flexibility, small batch production, and eco-friendly printing with water-based inks.

Types of Textile Fabric Printing Machines

When you search for a textile fabric printing machine, you will see many options. Each has its own use depending on fabric type and business needs.

1. Digital Textile Fabric Printing Machine

Works like an inkjet printer but for fabric.

Best for short runs, custom designs, and high detail.

Common in fashion, sportswear, and custom apparel.

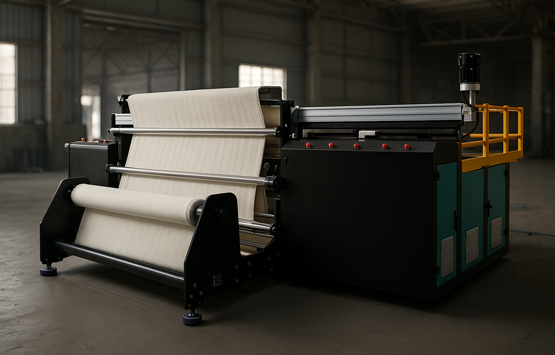

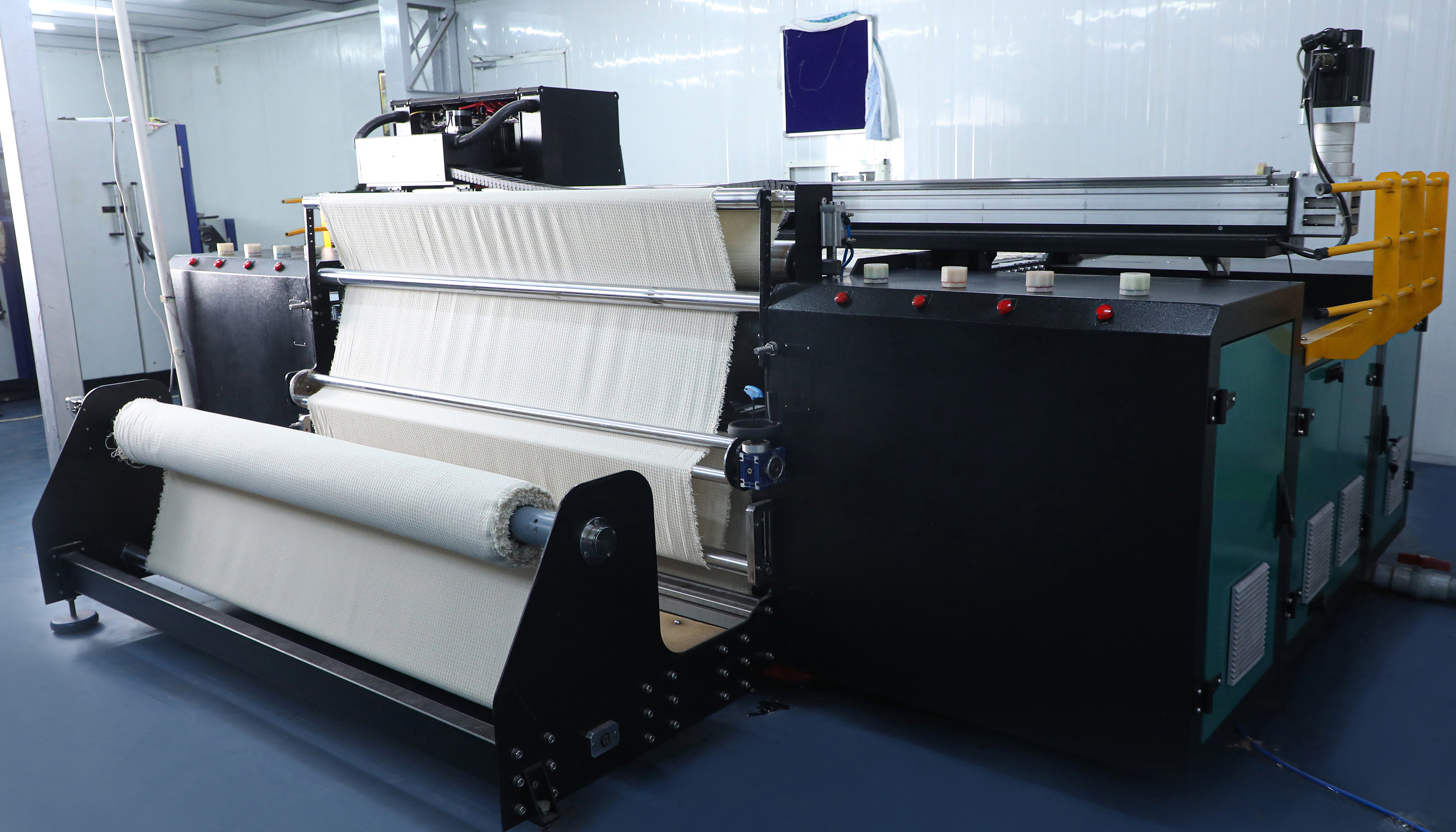

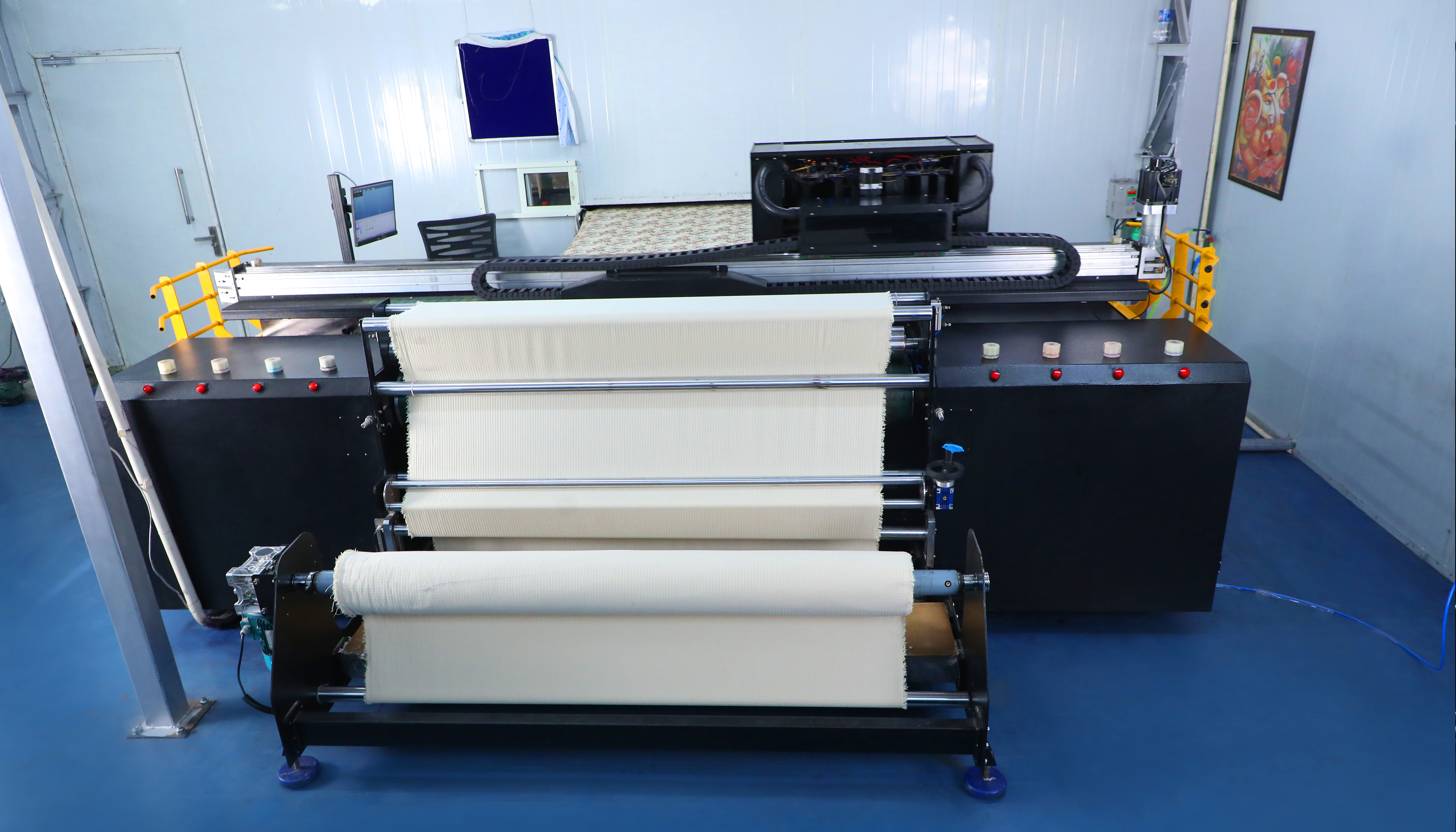

2. Rotary Textile Fabric Printing Machine

Uses engraved rollers to transfer designs onto fabric.

Suitable for bulk production.

Faster than digital machines but less flexible for design changes.

3. Flatbed Textile Fabric Printing Machine

Prints using flat screens.

Mostly used for traditional textile industries.

Good for medium production.

4. Sublimation Textile Fabric Printing Machine

Transfers design onto polyester fabric using heat and pressure.

Perfect for sportswear, flags, and polyester-based materials.

5. Pigment Textile Fabric Printing Machine

Uses pigment-based inks that bind directly to fabric.

No need for pre-treatment or post-washing in many cases.

Each textile fabric printing machine has pros and cons, so choosing the right one depends on your production volume, fabric type, and design needs.

Why Choose a Textile Fabric Printing Machine?

Investing in a textile fabric printing machine brings many advantages:

High Precision – Digital models allow fine detailing and photo-quality prints.

Speed – Machines can print meters of fabric in a short time.

Cost Efficiency – Reduces waste and minimizes labor costs.

Eco-Friendly Options – Many machines now use water-based inks and less water than traditional dyeing.

Customization – Easy to produce personalized designs and small batches.

Versatility – Works on cotton, silk, polyester, linen, and blends.

Applications of Textile Fabric Printing Machines

A textile fabric printing machine can be used in many industries:

Fashion & Apparel – Dresses, shirts, scarves, and more.

Home Furnishing – Curtains, bedsheets, upholstery.

Sportswear – Jerseys, shorts, polyester-based outfits.

Flags & Banners – Durable prints for outdoor use.

Custom Merchandise – Tote bags, fabric gifts, and personalized items.

Things to Consider Before Buying a Textile Fabric Printing Machine

If you are planning to buy a textile fabric printing machine, here are key factors to check:

1. Fabric Compatibility

Not all machines can print on every fabric. Digital printers work well on cotton and blends, while sublimation is only for polyester.

2. Print Speed

For bulk orders, choose a machine with higher meters/hour output.

3. Maintenance and Support

A textile fabric printing machine needs regular maintenance. Ensure the company provides training, spare parts, and service.

4. Cost and Budget

The cost of a textile fabric printing machine depends on type, capacity, and features. Always calculate not just machine cost but also ink, power, and maintenance costs.

5. Software Compatibility

Modern digital textile fabric printing machines come with software for design control. Make sure it supports common file formats.

6. Durability and Warranty

Look for a machine with at least 1-year warranty and reliable after-sales support.

How a Textile Fabric Printing Machine Works

Design Creation – The artwork is prepared on a computer.

Pre-Treatment – Some fabrics need coating for better ink absorption.

Printing – The textile fabric printing machine transfers the design onto the fabric.

Fixation – Heat or steam is used to fix the colors.

Finishing – The fabric is washed and dried before delivery.

Advantages of Digital Textile Fabric Printing Machines

Digital technology has changed the printing industry. Here’s why many businesses prefer digital textile fabric printing machines:

No need for screens or rollers.

Quick turnaround for small orders.

Allows unlimited color combinations.

Reduces waste and water usage.

Easy to print photographic designs.

Future of Textile Fabric Printing Machines

The future of the textile fabric printing machine industry looks strong. With demand for sustainable fashion and personalized products, digital textile printing is expected to grow rapidly.

New technologies like pigment ink advancements, automation, and AI-driven design tools will make textile fabric printing machines even faster and more eco-friendly.

Tips for Maintaining a Textile Fabric Printing Machine

To get the best results and long life from your textile fabric printing machine:

Clean nozzles regularly.

Use only recommended inks.

Keep fabric dust-free before printing.

Schedule professional servicing on time.

Store inks properly to avoid clogging.

Conclusion

A textile fabric printing machine is an essential investment for businesses in fashion, home furnishing, and custom merchandise. From rotary to digital, each type has unique benefits. Before buying, check your production needs, budget, and support options.

With the right textile fabric printing machine, you can produce high-quality prints, save time, and grow your business with ease.

Keyword Stuffing Recap (used throughout naturally):

textile fabric printing machine

digital textile fabric printing machine

pigment textile fabric printing machine

sublimation textile fabric printing machine

FAQs

What is a textile fabric printing machine?

A textile fabric printing machine is a device that prints designs directly onto different types of fabrics.Which fabrics can a textile fabric printing machine print on?

A textile fabric printing machine can print on cotton, polyester, silk, linen, and blended fabrics.What is the difference between digital and rotary textile fabric printing machines?

Digital textile fabric printing machines are best for small runs and detailed designs, while rotary machines are faster and better for bulk printing.Is a digital textile fabric printing machine eco-friendly?

Yes, digital textile fabric printing machines use less water and eco-friendly inks compared to traditional methods.How much does a textile fabric printing machine cost?

The cost of a textile fabric printing machine depends on the type, speed, and features, ranging from small-scale to industrial models.